If there’s one thing 2020 has proven it’s that the world around us can all change in an instant. That’s a harrowing revelation if you aren’t prepared to adapt, but a critical opportunity for growth if you are.

As much of the world’s population continues to adapt to social distancing and remote work, technological innovation is making that pivot easier. Organizational services like Microsoft Teams, WebEx, Skype and others are helping teams stay in contact and stay agile while collaborating. Meanwhile, DornerWorks web and mobile engineers have been developing our own web and mobile apps to help them adapt to new social distancing requirements, no matter the potential threat.

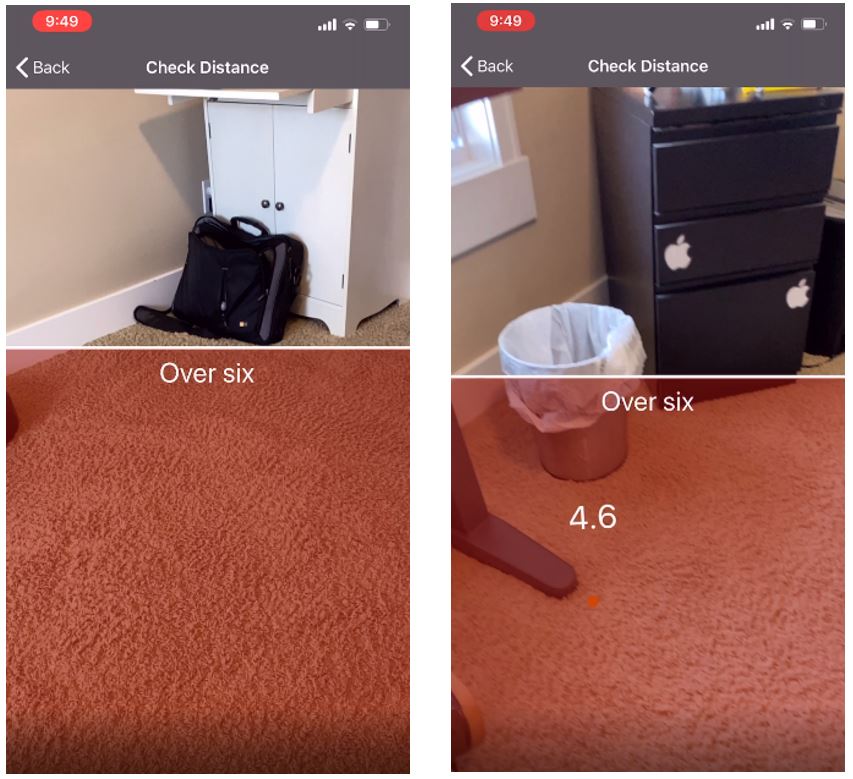

An early design combined augmented reality (AR) with recommended physical distancing guidelines to help users clearly see whether objects in view of a smartphone camera are inside or outside of a 6-foot distance. Based on Apple’s ARKit, this simple tool demonstrates a way that companies can incorporate AR into products they want to launch on the App Store.

For other purposes, the 6-foot radius could be extended or reduced to fit different requirements. In situations where safety measures include strict distancing guidelines, this example provides a great starting point for companies to build on and adapt to their own needs.

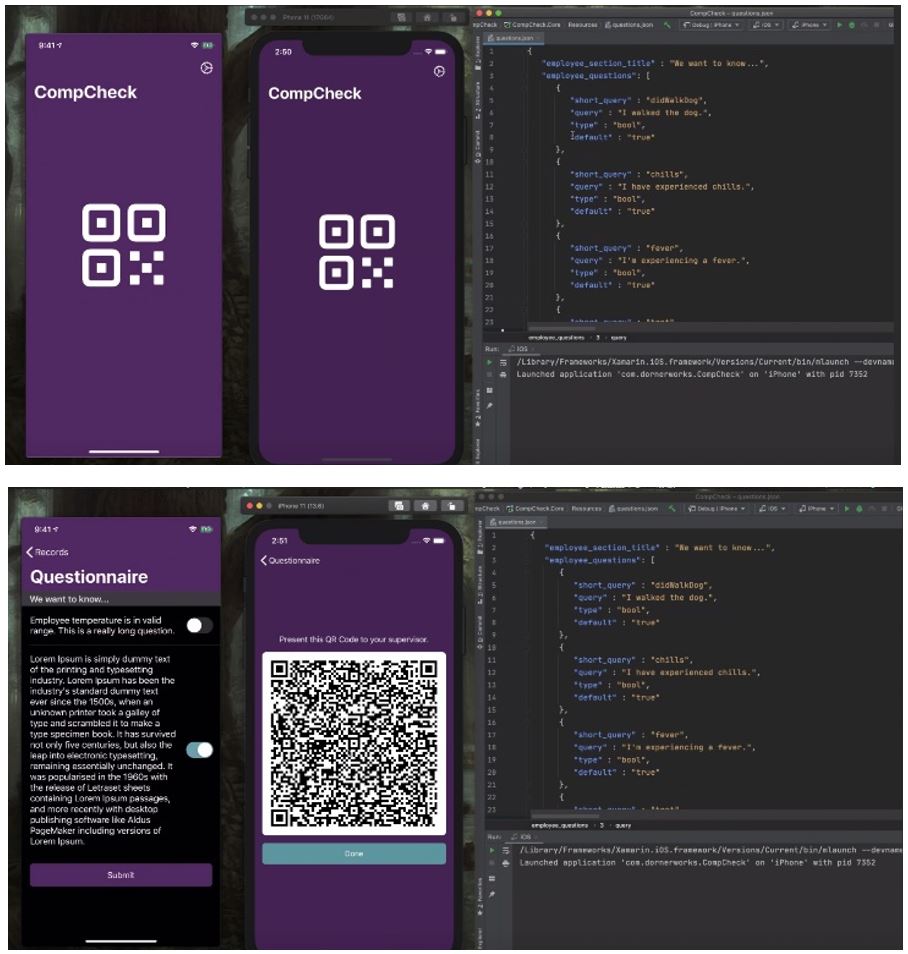

CompCheck, a lightweight checklist application, started off as an app built on JSON files shared by QR codes. A user answers a series of questions and shares the resulting QR code with a manager, who logs the information and takes the appropriate next steps. In one case, that may be allowing an employee to work a shift as planned or else remain home if any COVID-related symptoms are reported. In another, it could help surgical teams ready for an operation, or flight controllers ensure an aircraft is ready for takeoff.

“It can be used for pretty much any compliance requirement a company might run into,” says Mobile Application Development engineer Brandon Butler.

The current iteration of CompCheck operates without the need of a server, which make it more cost-effective and easier to set up. For enterprise companies, a private server-based version could be built with a little extra configuration.

Social distancing requirements have highlighted the fact that remote asset management can protect the health of humans and businesses alike. Whether that requires building new applications from the ground up or enhancing existing ones with technologies like augmented reality, location services, or streaming video and sensor data, DornerWorks’ customers are proof positive that IoT engineering guidance can create transformative growth.

For Dexter Laundry, a DornerWorks-developed solution is, among other benefits, helping laundromat owners understand more about how their equipment is being used and when maintenance services may be needed by providing remote configuration management tools and real-time alerts of equipment errors. This reduces the need to inspect every machine on routine in-person service calls or manually adjust settings physically on each machine, adding an extra layer of safety to the process. This solution was developed before global pandemic made social distancing the new normal but exemplifies the foresight and innovative engineering that DornerWorks brings to each project.

Over-the-Air (OTA) updates are making it easier for products like the several dozen models of Traeger Grills to receive updates without manually reconfiguring the firmware. Steeper Group’s Espire Elbow can also be updated via OTA upgrade directly from a doctor without the need for a field technician to manually upgrade the firmware in the field. Like Dexter Laundry’s connected industrial machines, these examples were also built pre-pandemic, but there is no denying the importance of developing new products with built-in OTA technology in a world where it is beneficial to limit or eliminate visits by field technicians.

In short, distance is not an obstacle to innovation. DornerWorks IoT engineering services will help you develop innovative products that grow your business regardless of distance.

Product developers want to know they are making the right decisions when it comes to connecting their products. We help them build transformational user experiences with confidence. Contact us to schedule your first meeting when you are ready to turn your ideas into reality.